Wall washer strip lights are a popular choice for both residential and commercial lighting applications. Two materials commonly used in the manufacturing of these lights are silicone and polyvinyl chloride (PVC). In this article, we will compare the advantages and disadvantages of silicone extrusion technology and PVC in wall washer strip lights.

The Disadvantages of PVC in Construction and Manufacturing

Polyvinyl chloride (PVC) is a popular plastic material used in construction and manufacturing. While PVC offers some benefits, such as being lightweight and affordable, it also has several significant disadvantages that should be considered. In this article, we will explore the drawbacks of PVC in construction and manufacturing.

Environmental Impact

One of the most significant disadvantages of PVC is its negative impact on the environment. PVC is made from petroleum, a non-renewable resource, and the manufacturing process produces toxic chemicals and emissions that contribute to air and water pollution. Additionally, PVC is not biodegradable, meaning that it can persist in the environment for hundreds of years.

Health Risks

PVC also poses health risks to both workers and consumers. The manufacturing process releases toxic chemicals, such as dioxins, which can cause cancer, respiratory problems, and other health issues. Additionally, PVC products can leach harmful chemicals, such as phthalates, into food and water, posing a risk to consumers.

Fire Hazard

PVC is also highly flammable, making it a fire hazard in construction and manufacturing. When PVC catches fire, it releases toxic gases, including hydrogen chloride and dioxins, which can pose a serious health risk to anyone nearby. Additionally, the burning of PVC produces a large amount of smoke, which can make it difficult for firefighters to extinguish the fire.

Brittleness and Short Lifespan

PVC can become brittle over time, especially when exposed to UV radiation and extreme temperatures. This can lead to cracks, fractures, and other damage, reducing the lifespan of PVC products. In construction, PVC pipes can become weak and brittle, leading to leaks and other problems. This can result in costly repairs and replacements.

Difficulty in Recycling

While PVC can technically be recycled, it is a difficult and expensive process. PVC products must be separated from other plastics, and the recycling process requires specialized equipment and technology. Additionally, recycled PVC products may not be as strong or durable as new PVC products, reducing their usefulness.

The advantages of Silicone Extrusion Technology of Wall Washer Lights

Silicone extrusion technology has revolutionized the way wall washer lights are manufactured. This innovative technique offers several benefits over traditional methods, including increased efficiency, durability, and flexibility. In this article, we will explore the advantages of silicone extrusion technology for wall washer lights.

Efficiency Boost

Silicone extrusion technology enables the production of wall washer lights with a single piece of material. This means that there are no joints or seams, which can create weak points and reduce the efficiency of the light. With silicone extrusion, the light is produced in a continuous process, resulting in a seamless, uniform product. The lack of seams also reduces the risk of moisture and dust ingress, which can further improve the efficiency of the light.

Durability and Longevity

Wall washer lights made with silicone extrusion technology are highly durable and long-lasting. The silicone material used in the extrusion process is resistant to UV radiation, extreme temperatures, and harsh chemicals. This makes it ideal for use in outdoor environments where the lights are exposed to the elements. Additionally, the lack of seams and joints reduces the risk of damage from wear and tear, ensuring that the lights last for many years.

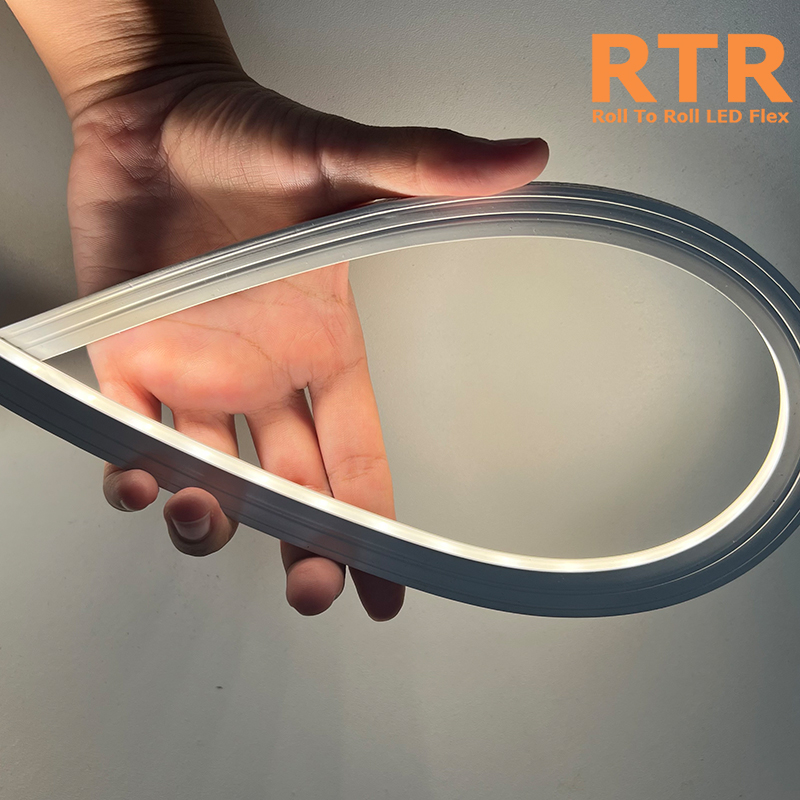

Flexibility in Design

Silicone extrusion technology offers significant flexibility in the design of wall washer lights. Manufacturers can create lights in a wide range of shapes and sizes, with varying degrees of curvature. This makes it possible to create lights that fit seamlessly into any environment, from curved walls to irregular surfaces. The flexibility of silicone extrusion technology also allows for the creation of custom designs, enabling manufacturers to meet the specific needs of their clients.

Ease of Installation

Wall washer lights made with silicone extrusion technology are easy to install. The seamless design of the lights means that there are no screws or fasteners required, reducing the installation time and effort. Additionally, the lights are lightweight and easy to handle, making them simple to position and mount.

Conclusion

In summary, silicone extrusion technology offers several benefits for the manufacturing of wall washer lights. The efficiency boost, durability and longevity, flexibility in design, and ease of installation make it an ideal choice for manufacturers. As the demand for high-quality, energy-efficient lighting continues to grow, we can expect to see more manufacturers adopting silicone extrusion technology in the production of wall washer lights.

Email: intsale13@rtrled.com