Light Emitting Diodes (LEDs) have become the preferred lighting choice in recent years, given their energy efficiency, durability, and versatility. LED strip lights, in particular, have gained enormous popularity due to their flexible design, ease of installation, and wide range of applications. Advanced extrusion technology combines with a high-quality silicone material to create silicone integrated extrusion LED strip lights, which further enhance these features.

Silicone Integrated Extrusion Process

Silicone integrated extrusion is a manufacturing process that involves the continuous extrusion of a silicone material, encapsulating the LED strip lights within. This process not only ensures a uniform and seamless finish but also provides several advantages over traditional LED strip light designs, such as improved durability, flexibility, and waterproofing.

The manufacturing process begins with the preparation of a high-quality silicone material, typically in the form of a liquid or gel. This material is then passed through an extrusion machine, where it forms a continuous tube or sheath around the LED strip lights. The resulting product features a smooth and uniform surface, with the LED chips and electronic components fully encapsulated within the silicone material.

Key Features

Silicone integrated extrusion LED strip lights offer several unique features that make them an attractive choice for various applications, including:

- Durability: The silicone material in these strip lights provides excellent protection against physical impacts, abrasions, and environmental factors such as UV radiation and temperature fluctuations.

- Waterproofing: Due to the complete encapsulation of the LEDs and electronic components within the silicone material, these strip lights exhibit superior waterproofing capabilities, making them suitable for use in both indoor and outdoor applications.

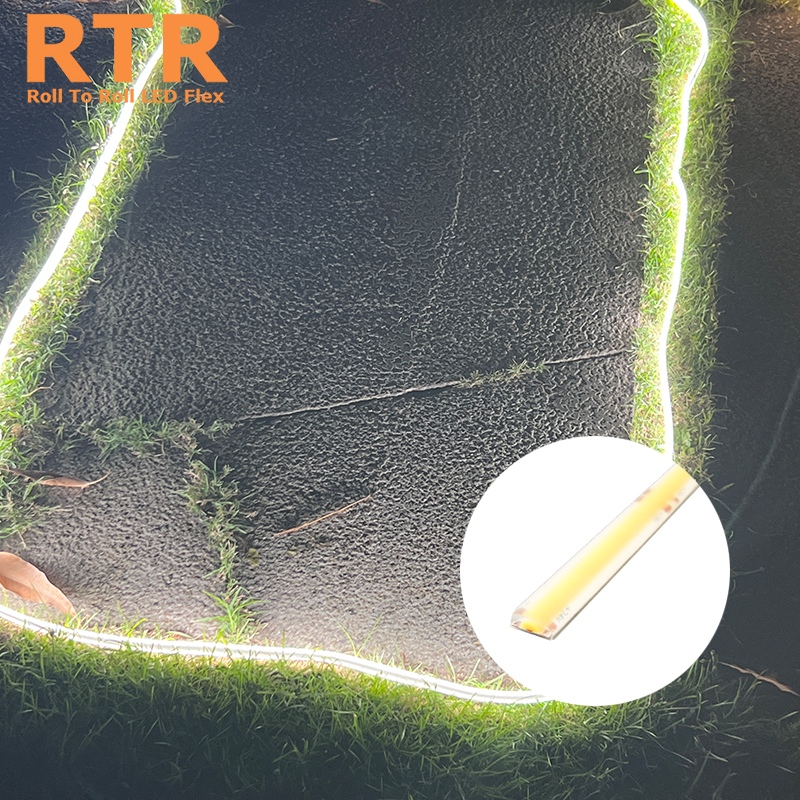

- Flexibility: The silicone material lends itself to greater flexibility than traditional PVC or epoxy resin materials, allowing for easier installation in tight spaces or around curves and corners.

- Heat Dissipation: Silicone’s high thermal conductivity enables efficient heat dissipation, ensuring the longevity of the LED strip lights and reducing the risk of premature failure.

- Customizability: Silicone integrated extrusion LED strip lights are available in various color temperatures, brightness levels, and lengths, allowing for a high degree of customization to suit specific requirements.

Applications

Due to their unique features and benefits, silicone integrated extrusion LED strip lights have found a wide range of applications, such as:

- Residential Lighting: These strip lights provide a seamless and aesthetically pleasing lighting solution for homes, including under-cabinet lighting, cove lighting, and accent lighting.

- Commercial Lighting:In commercial settings, these strip lights can be used for retail display lighting, architectural lighting, and signage illumination.

- Outdoor Lighting: With their waterproof capabilities, these strip lights are ideal for outdoor applications like landscape lighting, pool lighting, and exterior building accent lighting.

- Industrial Lighting: The durability and heat dissipation properties of these strip lights make them suitable for use in harsh industrial environments, such as machine lighting, warehouse lighting, and task lighting.

Conclusion

Silicone integrated extrusion LED strip lights represent a significant innovation in the field of lighting technology. Combining the benefits of LED lighting with the protective and versatile properties of silicone, these strip lights offer a durable, flexible, and waterproof lighting solution for various applications. As the demand for energy-efficient and customizable lighting options continues to grow, lighting designers are looking to silicone integrated extrusion LED strip lights to play a significant role in shaping the future of lighting design.